**Heads up: This post contains affiliate links. As an Amazon Associate, I earn from qualifying purchases. Meaning I may receive a small commission– at no cost to you, of course– were you to make a purchase through any of the links. If I link to a product, I use it, I love it, and I think you would too! Please see my Privacy Policy for more details.**

Table of Contents

- Beginner Terms To Know

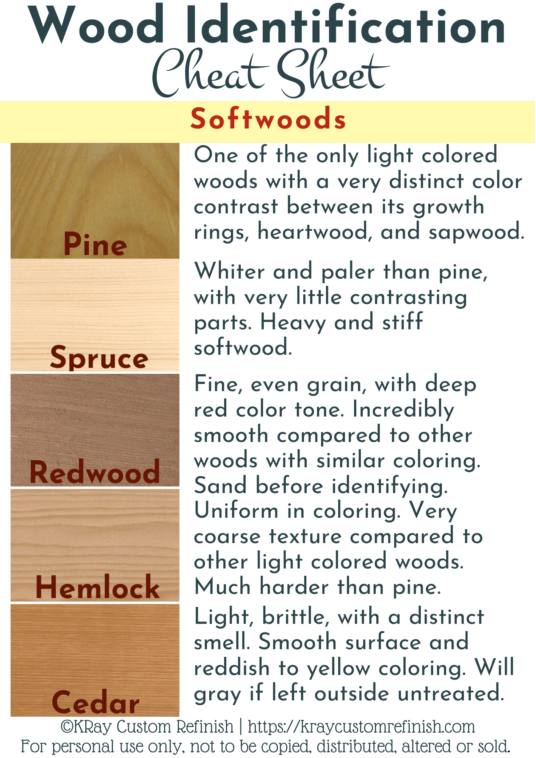

- Common Softwoods Used in Furniture

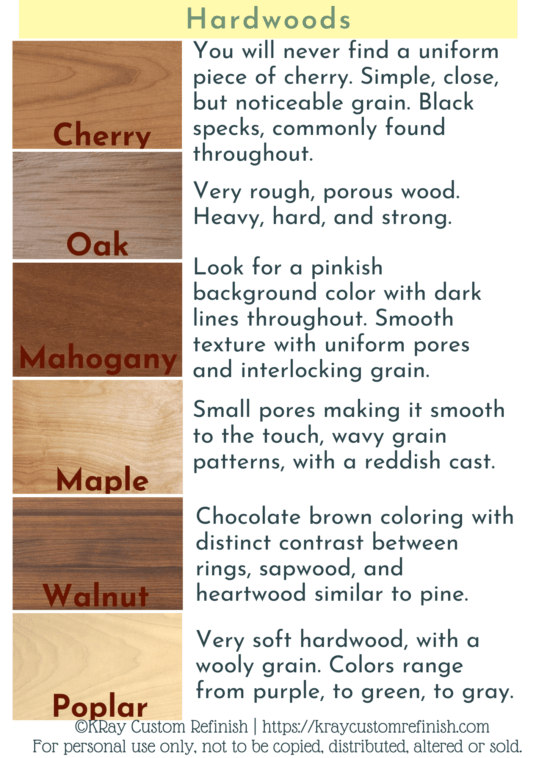

- Common Hardwoods Used in Furniture

- Free Printable Wood Type Identification Cheat Sheet

- Grain – Investigating Your Furniture’s Wood Identity

Hello everyone! If you’ve been wondering where I’ve been, I hope you’ll understand when you see how long and informative this post is!

I’ve been planning on writing this post, pretty much, since I started this blog. It has been one of the things I’ve always needed help with. I’ve spent hours researching this topic for each particular piece.

Knowing the answer to this question matters a great deal in restoration work. It will affect your strategy for sanding, pre-treating, and staining; basically, everything depends on knowing:

What type of wood is this??

You don’t want to start a refinish job in which you plan to expose the natural wood, without knowing the wood type.

Of course, there are SO MANY types of wood, it’s incredible. Even the experts sometimes can’t quite narrow down the exact species of wood you may be dealing with.

There are also multiple “subgenus” and “species” of each “genus” of wood. (i.e. Sub Genus: White Birch, Red Oak; Species: Acer pseudoplatanus)

You probably don’t need to know all of these crazy names for simple refinish work

To identify the exact species of the wood, you would need to know exactly where the wood came from in most cases. This is normally not possible, if (like me) you’re looking at a random piece of furniture you just snagged off the side of the road.

So for now, we will just be working on identifying the Genus (Birch, Oak, etc.) and not the exact Species of Wood. Also, we will stick to common wood types used in furniture making through the decades.

My list was filled with about 25 wood types at first. Then I decided I’d narrowed it down to the “most common” before my (and your) head exploded. I may add to the list periodically if I happen to find a furniture piece made of a wood type that’s not on it. (EDIT: Instead, I made an eBook with 39 wood types included for you to compare your furniture piece to. Check it out at the bottom of this post)

Identifying Wood Types In Furniture – The Most Common Wood Types

Hardwoods:

- Oak

- Maple

- Mahogany

- Cherry

- Walnut

- Poplar

- Rubberwood

Softwoods:

- Pine

- Spruce

- Redwood

- Hemlock

- Cedar

I will give you a short “Layman’s Terms” description of each type, and a distinguishing feature of each to help you identify it. (Of course, some wood types don’t quite have a distinguishing feature, but I’ll help you with that when we get to it.)

Before we begin, there are a few terms you should know that I couldn’t quite fit into the “Layman’s” category.

Beginner Terms to Know

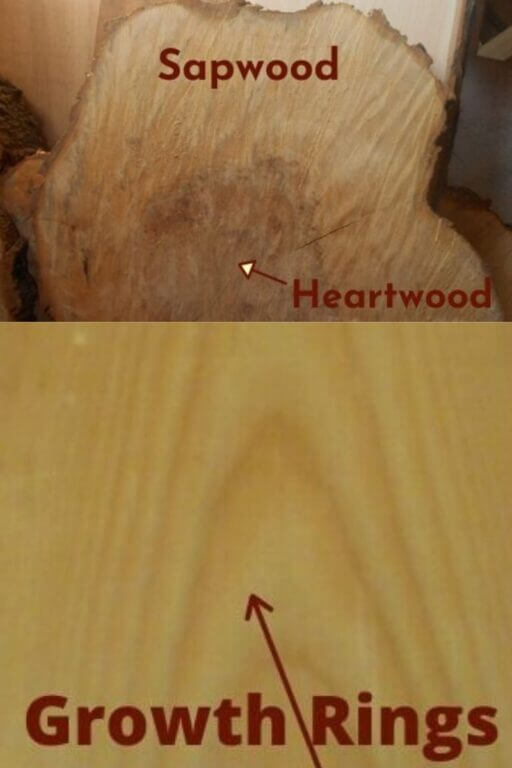

Heartwood & Sapwood

Every tree has each of these 2 parts. They are the inner and outer areas of the tree.

The Heartwood is the dead, inner section of the tree. Its coloring is usually darker than sapwood.

The Heartwood is also the older section of the tree, which dies as new sections grow around it. It doesn’t decay as long as the new growing sapwood surrounds it. It becomes stronger over time as the dead fibers get bound together.

Because of that strength, the Heartwood is the section of the tree best for woodwork. It is also less susceptible to fungus and contains less moisture, therefore it doesn’t shrink when dried.

The Sapwood is the outermost portion and is usually lighter, “new” wood.

The Sapwood acts as a pipeline for water to travel up the tree to the leaves.

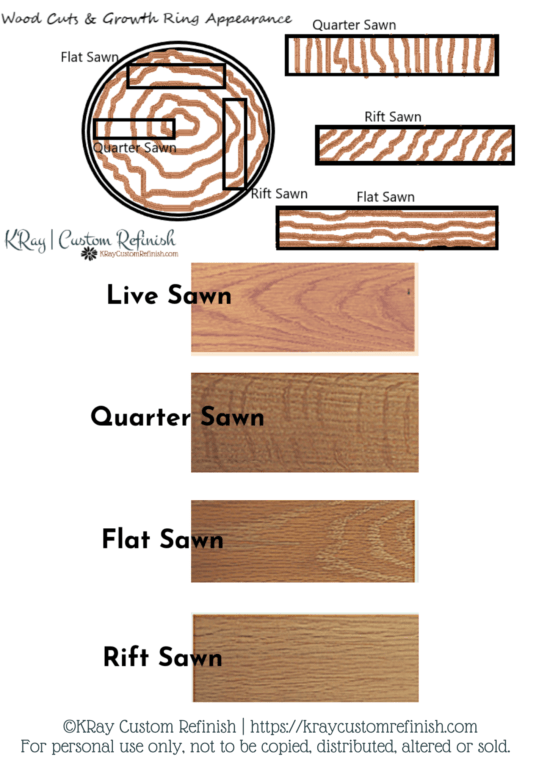

Growth Rings

All trees have annual growth rings. These are the cells formed each year that the tree grows. It is a cycle. The tree begins its new cycle of growth in the Spring and quickly forms a bunch of cells with thin, light-colored walls (earlywood). Thus the lighter section of the growth ring.

Then toward the end of Summer, growth slows down, and the cells are formed more slowly, smaller, and with thicker walls (latewood).

Thus making the dark sections of the growth ring. All this to prepare for Winter, in which the cells lay completely dormant. The following Spring, the cycle begins again.

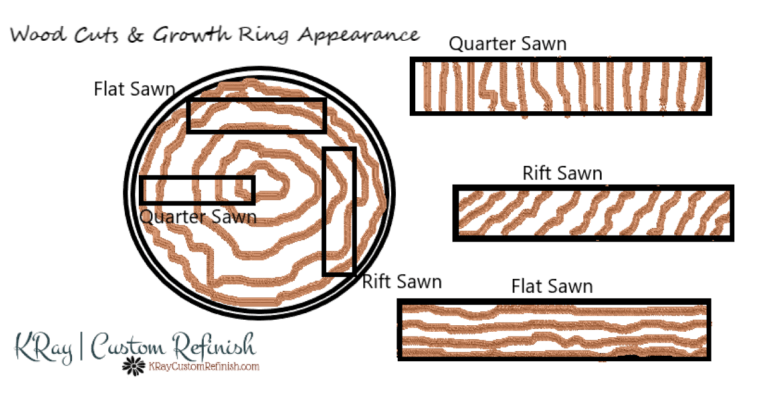

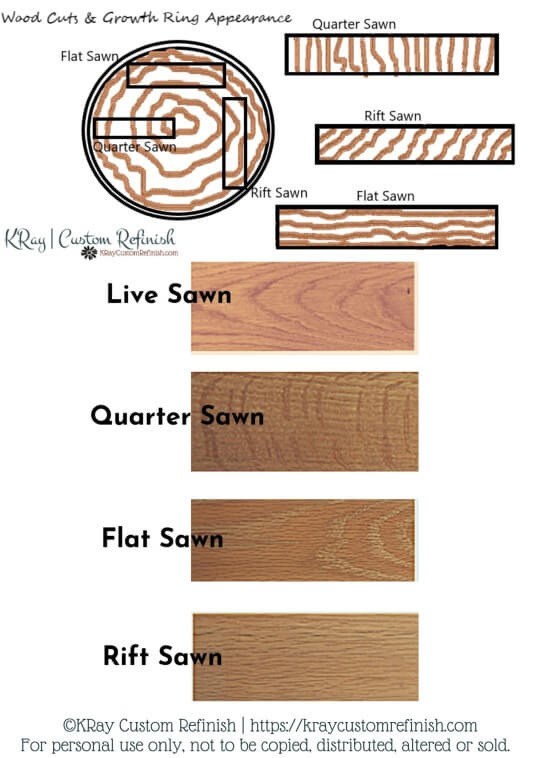

Growth rings won’t always show up on furniture wood as complete circle rings you’d see inside a tree trunk.

Depending on how that trunk is split into slabs, you will see many different patterns on the piece of wood.

The image below gives examples of the end-grain of wood pieces cut quarter-sawn, rift-sawn, or flat-sawn.

But the face of the board is more than likely what you’ll be rating the wood grain and patterns against.

Live Sawn is cut straight through the log without changing the orientation of the log at all. The entire log is used this way, straight through and through, and the most grain pattern shows as well.

You can see how the grain patterns change based on the cut, so be sure to match up the growth rings when trying to identify your piece.

You may think it doesn’t have much grain, but it may only be because of the way the log was cut.

Wood Grain

Wood Grain is the direction, texture, or pattern made from multiple fibers of the wood.

I’ve learned that the word “grain” happens to be used in many different ways in woodworking. It is a very versatile word!

You’ll hear descriptions of the grain “direction” or “pattern” i.e. straight-grained, wavy-grained, interlocked grain, diagonal-grained, and spiral-grained.

You’ll also hear descriptions of the grain “texture” i.e. fine-grained, coarse-grained, medium-grained.

Basically how large or small, the pores of the wood are. Large pores spaced very far from each other make for a coarse texture or grain. Small, tight pores make for a fine texture or grain.

Burls

A Burl is a part of the tree that grew, almost deformed, due to an injury or stress of some kind. It is used in furniture making quite frequently because when cut, burls usually have amazing grain patterns – unlike any other.

Burls are tough to identify with their wavy irregular wood grain.

If your piece has wavy or wild grain patterns, you may be dealing with burl wood and not just a certain wood type. Burlwood is rare, and quite expensive as well. So most of the time, if you see burlwood in furniture, it’s a thin wood veneer on top of a different kind of solid wood.

End Grain

The end grain view is one of the most important views when trying to identify your wood furniture piece. Non-porous woods are softwoods. Ring, semi-ring, and diffuse-porous woods are all hardwoods.

If you can’t sand your piece, look inside of drawers cabinets, trim boards, or even the bottom of legs for an untreated end grain view. It will really help you out with identification.

Now that we’ve covered those terms we should be all set to dive into identifying wood types in furniture

Once You’ve Identified Your Furniture’s Wood Type, These Wood Matched Repair Products on Amazon Are a Big Help with Restoration

Common Softwoods Used in Furniture

Pine

Pinewood is very common in less expensive furniture. There are several different types of Pine, but as I said, I’m going to try to stick with one Genus, and most Pine species have very similar characteristics.

Pine is usually easy to identify. Pine’s heartwood tends to be a light brown color, sometimes with reddish undertones.

While the sapwood is a white to pale yellow color.

You will find some that have dark brown knots and streaks. This is usually Knotty Pine. Normal pine wood has very little wood grain, but all Pines have a drastic difference between their heartwood and sapwood.

How to Identify Pine Wood in Furniture

You can usually identify Pine by the distinct difference in color between the growth rings, knots, and wood.

The dark and light parts of the growth rings in Pine have great contrast.

Of the light-colored woods like Pine, Spruce, and Birch, this contrast only happens in Pine.

Spruce and Birch have very few color variations between the growth rings, knots, heartwood, and sapwood. Their colors are more uniform giving it a dull subtle look.

Pine wood’s rings and knots always stand out making it more suitable for rustic farmhouse furniture.

Pine is often used in furniture but is considered “lesser quality” than other woods. I disagree with this, as do other woodworkers I know.

Yes, it is very soft, light wood, and some types are easily scratched and dented. But the contrast I spoke about earlier, is unmatched by other woods. The wood grain is beautiful, and honestly; not all Pine is soft.

I will agree that it’s tough to stain. It has very small pores, making it more difficult for the wood to absorb the stain.

When sanding Pine before staining, try to finish with lower grit sandpaper. 120 grit usually works best. This helps open the pores before applying the stain.

You may want to use a pre-stain conditioner or another method of preparing wood for stain such as black tea; to prevent uneven absorption.

I tested every pre-stain treatment method I could find in the 2 experiments below

Which Pre-Stain Treatment Works Best For Tough to Stain Woods?

Preparing Wood For Stain: The 1 Method You Should Be Using But Probably Aren’t

It’s a tricky one, but with the right method, you can achieve a gorgeous stain on Pinewood.

For more help with staining, check out How to Stain Wood. Your Questions Answered.

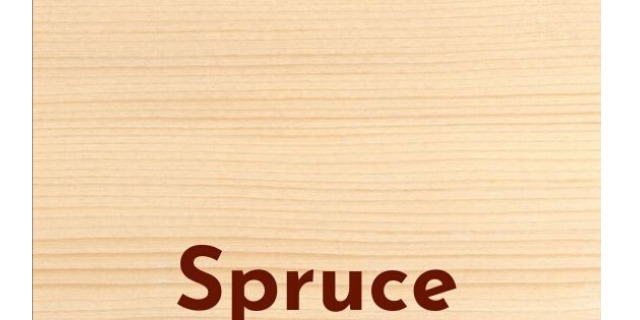

Spruce

As I mentioned above, Spruce is another light-colored wood. Usually a white to yellow color, sometimes with pink undertones. Unlike Pine, it’s very stiff for its weight.

Spruce is used a lot in construction because it is commonly found in large pieces with very similar, straight grain throughout. It also doesn’t weigh a lot for how strong it is, making it perfect for roof trusses and joists.

It has a very smooth texture and small pores.

How to Identify Spruce in Furniture

Spruce will look similar to pine with very little contrast between the heartwood and sapwood.

Spruce is whiter and paler than Pine. It’s also slightly heavier, stiffer, and won’t dent quite as easily.

You should treat Spruce the same as Pine when sanding or staining it.

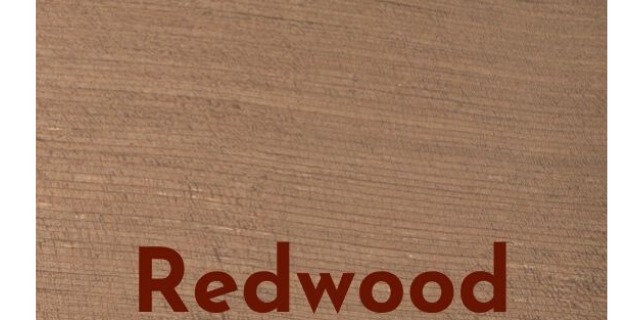

Redwood

Redwood comes from the tallest tree species on earth. Being so, it’s not the most common or cheap wood type for furniture. Redwood’s heartwood is light pink-brown to deep red-brown. Its sapwood is pale white or yellow.

You may find curly Redwood burls or spots with wavy grain; but normally it will have a very fine, straight grain.

It’s pretty soft and lightweight, but decently strong for its weight. It also resists rot and decay, so it’s sometimes found in outdoor furniture.

How to Identify Redwood in Furniture

Of softwoods, Redwood is usually the easiest to distinguish from Pine, Spruce, or Fir. Color alone will most likely be enough when deciding between boards at the lumber yard. But if you’re not positive it’s softwood, it gets a little trickier.

Redwood used for furniture is usually a high “clear” grade, with little to no imperfections or knots. You will find a fine, even grain, and deep red coloring. It will also be incredibly smooth compared to other wood types with similar coloring. If it’s an older piece that was left untreated and exposed to the weather, it may have turned a silver-grayish color.

Try sanding Redwood down to fresh wood to distinguish its true color.

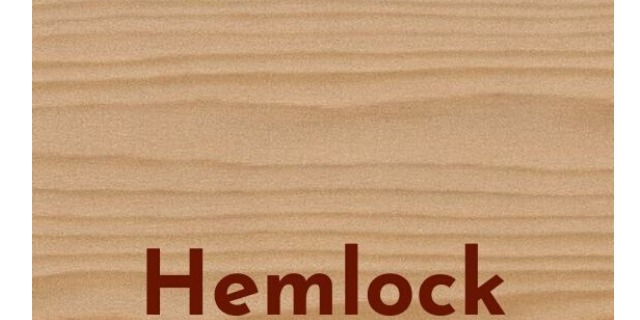

Hemlock

Hemlock is a softwood that is very hard and strong. It has a nice straight grain with an almost uniform coloring difference between heartwood and sapwood. You usually won’t be able to distinguish between the two.

It is resin-free meaning it accepts stains, paints, and clear finishes very well. Resin-free also means it doesn’t have anything to protect it from the elements, so it won’t be found in outdoor furniture.

How to Identify Hemlock in Furniture

As a lighter-colored wood type, if you have sanded your piece down to bare wood, you can easily distinguish Hemlock from other light woods like pine or spruce, again on how uniform the wood looks.

Pinewood’s contrast between its heartwood and sapwood is very large.

Hemlock has a very uniform coloring. It is also usually much harder than Pine.

It has a very coarse texture with large pores. Whereas most light-colored woods are on the smoother side.

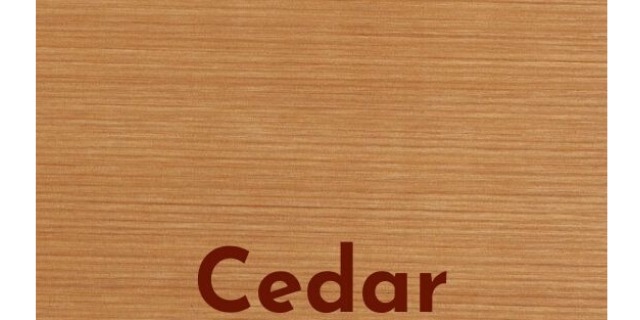

Cedar

Cedar is one of the easiest woods to identify due to its smell. The smell is a natural bug repellent, so people like to use it for inside closets or chests to keep linens and other items safe from insects and moisture.

It is also weather-resistant and works well for outdoor furniture. I offer Cedar as a wood option for my most recent product; Custom Made Planter Boxes because it’s the perfect wood for use in a garden! Plus, the coloring is just ah…a thing of beauty. 🙂

Cedar is very light, and brittle, and should not be bleached or stained—colors of cedar range from a light yellow-brown or reddish-brown heartwood to a pale yellow almost white sapwood. The color will darken and gray if left outside without treatment, or in direct sunlight for too long.

How To Identify Cedar in Furniture

The smell is usually a telltale sign you’re dealing with Cedar. I like to say it has a woody, evergreen/cat urine smell without the ammonia. (maybe way off on that description for some.)

Smell it once, and you’ll usually know Cedar from then on, anytime you smell it.

That smell plus the smooth surface of the wood with a reddish-brown/yellow coloring should help you narrow it down to Cedar.

If it’s an older piece that was left untreated and exposed to the weather, it may have turned a silver-grayish color.

Common Hardwoods Used in Furniture

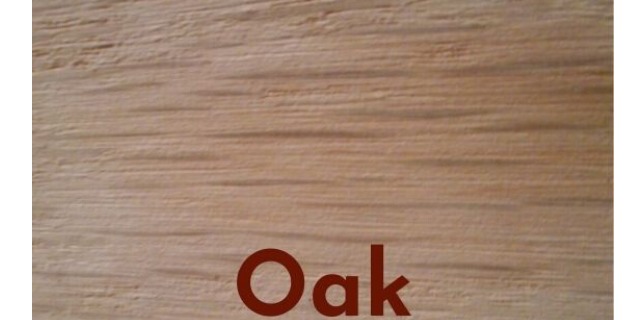

Oak

Oak is the most widely used hardwood. The 2 most common subgenera are Red Oak and White Oak. Both have very large pored, coarse textures.

Oak is ring-porous wood, meaning its end grain will have numerous large pores and small pores in separate groups together.

Oak is extremely hard and strong wood. It was used a lot in cabinets and flooring, although it does tend to yellow over time.

White Oak is more scratch, stain, and dust resistant than Red Oak. Red Oak will stain if it comes into contact with water.

How to Identify Oak in Furniture

You can usually determine whether a wood piece is oak by running your hand across the piece. If it’s completely smooth, chances are it’s not Oak.

Oak is a very rough, porous wood. If you have sanded your wood piece down to the fresh wood grain, you should feel that texture if the wood is oak.

It will also have an interesting grain pattern. Red Oak with its swirling wavy grain, and White Oak depending on its cut, yellow rays or flecks, or even a tiger stripe grain.

More often than not, you will see small dark horizontal lines throughout the piece also known as rays. White oak’s rays are usually at least an inch long, while red oak’s rays are shorter, usually around 1/2″ long.

Quarter Sawn Oak

Quarter Sawn Oak deserves its section as it is a very controversial subject. Many people think that this oak also known as “tiger oak” is an altogether different species of oak. But in fact, it is White Oak that has been Quarter Sawn. (which I discussed at the beginning of this article).

When Oak is cut Quarter Sawn it creates a certain pattern, unlike any other wood type.

They cut across the growth rings at 90 degrees, producing interesting specks or rays that resemble cat eyes. It is a very sought-after wood for furniture making and is very valuable if you own a piece of tiger oak.

Maple

Maple is my all-time favorite wood. I’ve worked on multiple pieces made completely of maple, and it’s tricky to work with. Its creamy light brown coloring has a reddish cast to it. It does accept stain, so you will sometimes find dark maples, but you can usually spot the wavy, curly grain with amazing swirling patterns.

Some people don’t like the way Maple looks when stained, as it’s crazy, swirling grain sometimes makes it look like you gave it a bad stain job. But if you look closely, it’s quite beautiful.

I Layered Stain on this maple seat. The grain swirls create a gorgeous look. The Child’s Rocking Chair pictured was made completely of Maple and is still available in my shop. EDIT: SOLD OUT.

How To Identify Maple in Furniture

Occasionally, you will find a piece of birch furniture stained to resemble Maple. Be sure to sand down your piece to bare wood to see its natural coloring. Birch is much lighter and does not have the reddish cast that Maple will always have.

Most Maple pieces will have a tight, straight grain to them. This is another type that I can usually determine by running my hand down a piece.

Maple has a very distinct feel to it, in my opinion. Its pores are tiny, and it’s incredibly smooth to the touch.

This is because Maple is a diffuse-porous wood. All of its pores are smaller and grouped tightly together creating a smoother surface.

It will also be on the softer side compared to other hardwoods. It is more durable than Pine but softer than Oak. Although on the softer side, it’s still a very tough wood to sand.

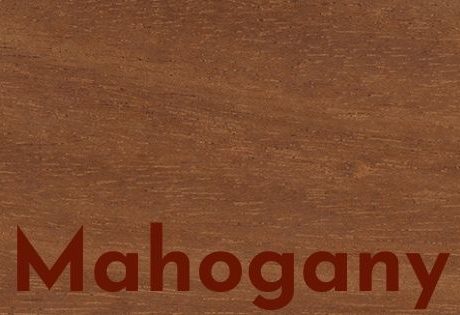

Mahogany

Mahogany is a tropical hardwood, that is very popular in more exotic furniture. It has a distinctive swirly grain that sometimes resembles ripples or ribbons. It has a very smooth texture with uniform pores that are very resistant to moisture, making Mahogany great outdoor furniture wood. The grain can also be found interlocked making for incredibly strong wood.

How to Identify Mahogany in Furniture

Mahogany’s main color is mostly reddish-brown, with some lighter colors also common. Although its accent colors can range from pink, white, peach, grey, and brown – making for exotic, unique-looking patterns.

When looking closely at your wood piece, look for a pinkish background color with dark lines throughout whatever color they may be.

Mahogany is also a diffuse-porous wood, with pores close together. But Mahogany’s pores are much larger than other diffuse-porous woods like Maple. So the texture will be on the rougher side.

Weight-wise, it is a lighter wood. It has the strength of Oak but weighs nowhere near as much.

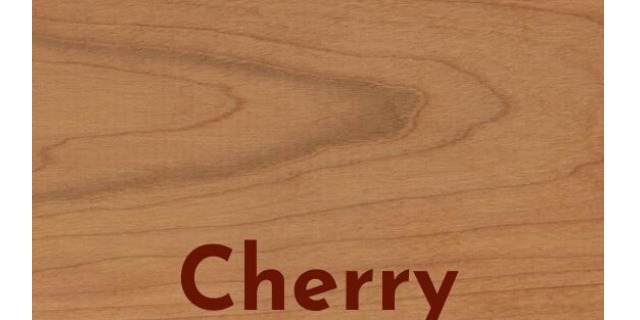

Cherry

Cherry is one of the most prized hardwoods for furniture makers in America. It has a very smooth grain and coloring that begins as a light pinkish color and then darkens over time to a dark reddish hue. It’s a photosensitive wood, meaning it darkens over time with exposure to light. The true color of cherry can range greatly from tree to tree, even sometimes from board to board on the same tree.

How To Identify Cherry in Furniture

One characteristic of cherry wood that is different from most others, is the “gum pockets” or “pitch pockets” that show up as black flecks in the wood. These are naturally occurring mineral deposits that form in the empty pockets, where sap used to be found. They are random but add character to cherry wood pieces.

Many pieces made to look like cherry wood, are uniform in color, with no black specks and no grain.

True cherry wood will have a simple, close grain, but a noticeable one as well. You’ll never find a “uniform” piece of cherry, so beware of fakes.

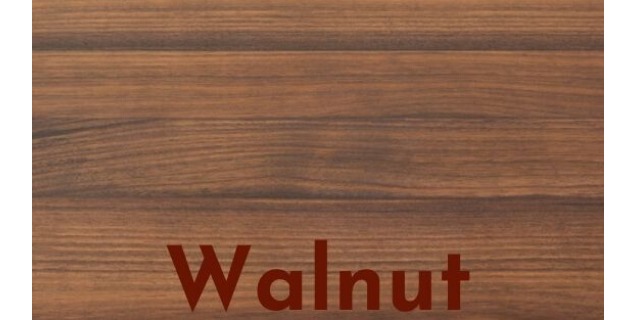

Walnut

Walnut is a strong, yet lightweight wood. It has a gorgeous chocolate brown coloring, with a usual straight grain. It’s also known for its burl wood pieces, with distinctive figured grain and dark streaks. Wood closer to the roots has more of a wavy grain than the straight-grained trunk.

How to Identify Walnut in Furniture

It’s tough to judge walnut wood on its grain pattern as it really can be all over the place. Normally it has a straight fine grain, but furniture makers love to seek out the super figured, patterned burls and knotted walnut pieces.

You can most likely identify it best by the chocolate brown coloring. All-natural walnut can range from a dark tan to chocolate brown, sometimes with streaks of green or purple in spots.

Similar to pine, Walnut’s growth rings and knots have a pretty distinct contrast from its heartwood and sapwood.

The contrast isn’t quite as strong as in Pine, but it’s something that stands out when trying to identify Walnut.

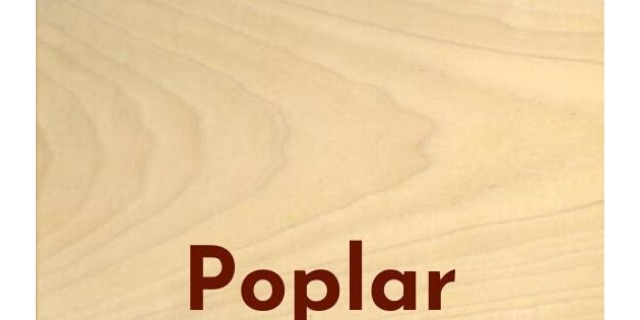

Poplar

For the longest time, I thought Poplar belonged in the softwood category, but it is a hardwood. It is the softest of hardwoods, as well as one of the most inexpensive. It seems to be kept in the same category as Pine; used on less expensive furniture, or under veneer pieces.

It may not be as rugged as other hardwoods, but I’m a big fan of Poplar! I’ve restored multiple veneer pieces by removing the veneer and staining the gorgeous Poplar underneath.

I discovered the top, and drawer fronts of this gorgeous sideboard were Poplar after stripping its veneer. You will want to be careful if you plan to attempt removing the veneer from Poplar. It is extremely soft and easy to dent and scratch.

Make sure you loosen the veneer as well as you can before you attempt pulling it from the wood beneath. If you fail to do this you will end up pulling up chunks of poplar with the veneer and glue. Trust me, I’ve done it.

But, I figured out the best way to remove wood veneer to help with that problem. If you’re interested in never regretting your choice to work on a veneer piece again, give it a read. (Plus there are a few more examples of Poplar for you to compare your piece to.)

How To Identify Poplar in Furniture

Poplar has a light cream to yellowish-brown heartwood, but green, grey, and even purple streaks are quite common when looking at a piece. That’s usually the safest bet when identifying poplar, but it’s not definite that you’ll see those colors in your particular piece.

Another easy way to determine if your piece is poplar is by feeling the wooly grain.

It has a wooly type grain that you will notice either by running your hand over the piece or, some people say they can even notice the somewhat hazy look of the wood from the wool.

This can also affect your outcome while staining your piece, so be sure to use finer sandpaper to finish and remove the wooliness.

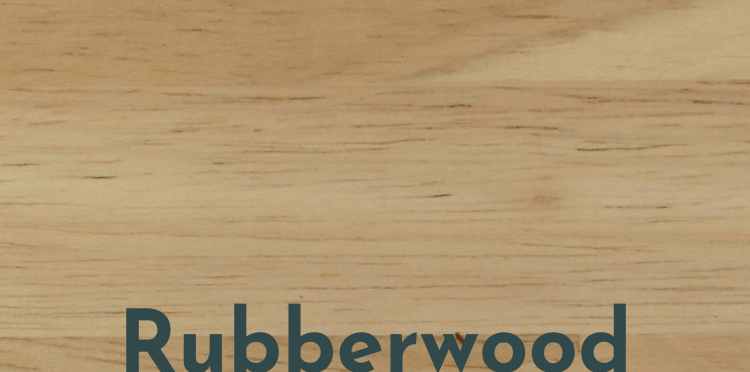

Rubberwood

I decided to add Rubberwood to this list recently due to the number of Rubberwood furniture pieces I’ve seen lately. It’s more commonly found in furniture made after the 1980s.

Rubberwood is usually found in Asian imported furniture carried by big-box retailers and home furnishing stores like IKEA. Yes, it’s cheaper, but I think it’s a nice wood for refinishing.

Rubberwood furniture sold by home furnishing retailers is most often either painted or stained to resemble other wood types. The unfinished, natural wood color is usually a light tan to pale peach color. It almost resembles a soft maple but with much larger pores and coarser grain.

How To Identify Rubberwood in Furniture

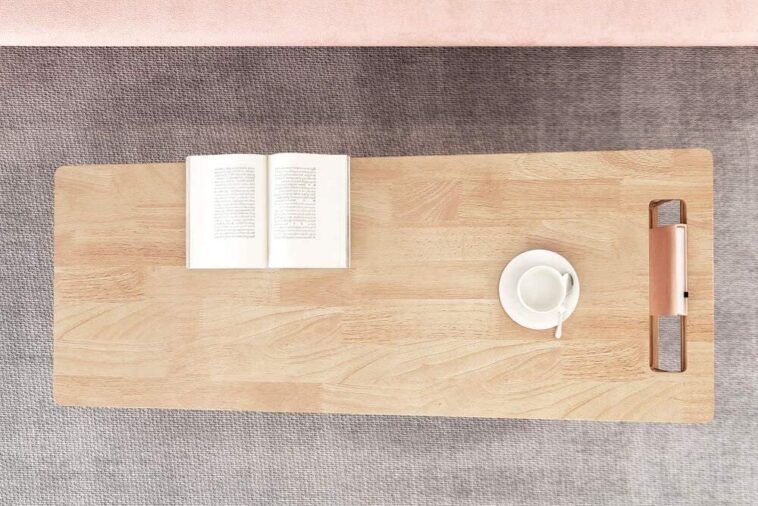

There is usually one very distinguishing feature of Rubberwood furniture. Tabletops, benches, or other larger surfaces are usually not made of a single, solid piece of wood.

For numerous reasons, Rubberwood surfaces tend to be multiple smaller pieces of Rubberwood finger-jointed or butt-jointed together. (See Below Image)

Each piece has notches carved out and then they are glued together like a puzzle. The exact reason for this is unknown, but it’s most likely due to the size of the Rubberwood trees, as well as the stability of the end product.

This isn’t very common with other wood types, at least in furniture construction. So if your piece looks something like the above swing coffee table from Amazon — no matter the color– it’s most likely Rubberwood.

As for finishing Rubberwood, one tip I can give you is to make sure you double-check and resand the joints of these larger surfaces before staining. As these joints are glued together at the factory, extra glue may still be on the wood in those spots that you won’t see until it’s too late.

If there is leftover glue residue on the wood, those areas will not absorb wood stain, and you’ll end up with a bunch of uneven areas on your piece.

Free Printable Wood Type Identification Cheat Sheet

Want a more visual explanation of each of the 12 wood types I mentioned? Download a free cheat sheet with images and a summary of each type so you can make your comparisons.

Click to get your free download or head to my DIY Resources page for that, and much more!

And there we have it! PHEW! If after reading you STILL have no clue what type of wood your piece is, definitely check out my new eBook, “Grain.”

I go more in-depth into each of these wood types plus 27 other wood types commonly found in furniture! 27!

PLUS finishing tips and specific help on every one of the 39 total wood types included.

Grain – Investigating Your Furniture’s Wood Identity Interactive eBook

I’m very excited about my newest resource Grain, which will truly help you identify your wood furniture piece step-by-step using image comparisons of the piece’s color, grain, texture, figure, weight, and more!

Thanks much for reading!

Until Next Time,

KRay

I never knew that different wood species can transform the appearance of a furniture piece. My aunt asked me for tips on how to do her home appeal upgrade and I want to help her out. Perhaps investing in new furniture can help her achieve this in the future.

I like your woodworking tips. I want to commission a toy for my son. I’ll have to talk to a carpenter.

I enjoyed your article. But I am still struggling to identify the wood used in a bedroom dresser made by John Widdicomb company in Grand Rapids, MI in the early 60’s. I would like to send you photos in hopes you can identify.

Absolutely! You can send them to [email protected] and I’d be happy to take a look.

Good article. I have a mission to identify wood my stairs are made of. House was build in circa 1980, terraced so it couldn’t be expensive. It is very reddish especially when oiled, but got lighter parts too. It doesn’t have any knots and it is very uniform.

i am trying to identify a wood that is part of a frame I am working on. The wood, has tiny flecks in it all over. The flecks look more like part of the wood species than worm/insect holes. These are not holes.

Hi Anne! Feel free to send me some photos at [email protected] and I’d love to take a look for you!

This came up 3rd on Google ,Answers every question you could Ever have about wood

Brilliant

I enjoyed this. Thank you.

Hi there, i read your blog from time to time and

i own a similar one and i was just curious if you get a lot

of spam responses? If so how do you reduce it,

any plugin or anything you can suggest? I get so much lately it’s driving me crazy so any help is very

much appreciated.

Hi,

I have received some wood to craft

I believe it’s door & window frame.

I have cut and sanded and the grain has a most beautiful sheen as if it has gold/copper in it…

I would be most interested if you could identify it .

Thank you 🌳

Sounds amazing! Send me some pictures at my email [email protected] and I’d love to check it out!

I really like how walnut has a straight fine grain that can give it a very distinct look. I might opt for that kind of material for the custom wood railings of my deck. That would surely give a very earthy vibe to the exterior of my house when working with such colors.

Yes I certainly do this has left my life in turmoyal and great depth and bad health .

Thanks for article. Unfortunately, I’m still struggling to figure out the wood we have on our stair railings. We decided that refinishing our stairs would be a great DIY project. We pulled up all the carpet, pulled out hundreds of nails and staples and spackled the nail holes on the white risers. Then we started to sand the oak stairs (60 yr old home) and railing. That’s when we started having problems. The curved sections of the spindles and newel post wasn’t easily sanded, even with many tries at it. Therefore, we did a little research and decided on a chemical stripper – only on the curved sections. The first stripper didn’t seem to have much impact so we tried a second stripper. That’s when we really ran into trouble. We followed the directions but this stripper actually permanently stained the wood where we applied it. We cleaned it, we even tried using bleach on one spindle to see if it would correct the darkened section. We’ve waited over 3 wks to see if it would lighten with time. No luck. We’ve now decided our best option is to just paint the spindles white. However, we don’t want our newel post white so we have to replace it. Here is where I’m hoping someone can help. We’re fairly sure that the railings, newel post and spindles are a different type of wood than the oak floor. We’re not planning to replace the railings – just the newel post – so we need to figure out what type of wood this is. Even with the great article above, we’re still not sure. I have photos of the railing. Is there a way for me to post the pics and get input on the type of wood that was used for the railing so we can match the wood for our newel post?

Any help would be greatly appreciated.

My goodness, that sounds like a serious pain in the butt! So sorry my article wasn’t enough to help! I don’t think you can comment with an image on my page unfortunately. If you have it uploaded somewhere with a URL you can send me, I’d love to take a look. Or feel free to email me at [email protected]. Look forward to hearing from you!

Good blog you have got here.. It’s hard to find good quality writing like yours nowadays.

I honestly appreciate people like you! Take care!!

Wow thank you so much! You made my day! I appreciate people like you!! 🙂